For more information about the Pfaff 1222E, check out my initial review as well as my tips on threading with industrial cones. Also you can replace the pedal if you have a “runaway” vintage sewing machine.

As many of you know, especially if you follow me on Facebook, I love my Pfaff. Since I’ve been getting a fair amount of site visitors looking for information on the machine, I’ve decided to do an update, now that I’ve been using the machine for about 6 weeks. To recap (and get those search results, cha ching) it’s a 1982 Pfaff 1222E.

This post will probably not be too interesting to most readers, but hopefully I can share some insight with people thinking about getting one of these machines. From what I can tell, the normal price range is $300-400, depending on the machine’s condition and accessories.

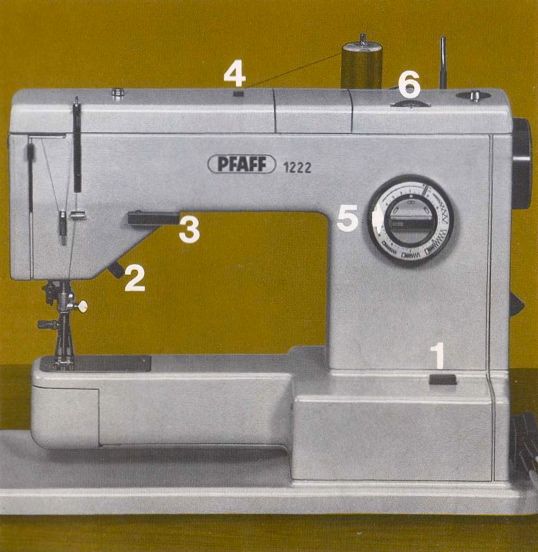

My machine came with a CD manual, which I’ve taken the instructional images from.

This is my first intentionally vintage machine. I learned to sew on a Singer that was probably made at the same time, but it didn’t seem vintage at the time. There have been plenty of older people (mostly women, although plenty of men have asked about that new sewing machine I constantly talk about on Facebook) who laugh at me when I tell them my vintage machine is from 1982, basically thinking I’m so young and naive to consider the early 80s vintage. If I were using a 30-year-old nail clipper, a tool that hasn’t really evolved much over its lifetime, I wouldn’t call it vintage. But a sewing machine that’s older than I am, in an industry that has seen lots of development and digital revolution, for which parts are no longer manufactured, in a throw-away culture? Yes, I consider that vintage, and if you think I’m naive for that then I think you’re outdated and delusional. So there.

I honestly haven’t used the table extension a single time. I do mostly apparel sewing, and the free arm actually works best for me. It’s smaller than on my last machine, and the perfect size for sleeves or legging hems, coming in at just over 9″. So while I’m definitely glad to have it, I’m glad I didn’t pay $50 for an acrylic table.

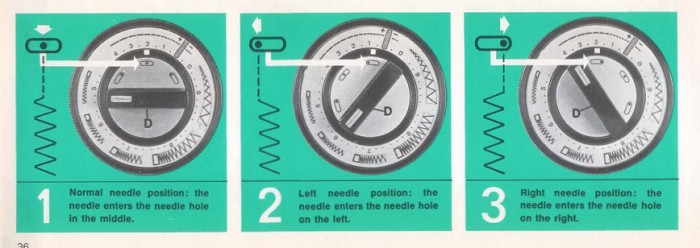

I’ve grown pretty fond of the setting dials. They are simple but very efficient! The outer ring adjusts stitch width and length, which makes sense if you look at the diagrams on it. The inner knob is for the needle position, which is essential in some of the decorative stitches, which are set through buttons on the top of the machine.

I’ve grown pretty fond of the setting dials. They are simple but very efficient! The outer ring adjusts stitch width and length, which makes sense if you look at the diagrams on it. The inner knob is for the needle position, which is essential in some of the decorative stitches, which are set through buttons on the top of the machine.

It took me a little while to figure out my favorite stitch settings, which I’ve marked with rhinestones. They’re removable if I ever change my preferences, and also delightful.

This dial also has a knob to adjust the needle position from left to right, which is essential for some of the decorative stitches.

Because you manually set the stitch settings (with dials), the machine doesn’t reset when you turn it off or move to a different stitch. This may be obvious, but it’s an extra step for those who are used to modern digitized machines.

One feature of the machine that may be worth noting is the automatic needle position: there is none. Whereas my last Singer would automatically pull the needle up to its highest position when I took my foot off the presser pedal (making it easy to pull the fabric out from the machine), and the industrial Juki I use at work puts the needle at its lowest position (so that I can pivot the fabric without losing my place), the Pfaff leaves the needle wherever in the stitch it is when I remove my foot. Despite the power and speed of the machine though, it’s pretty easy to take my foot off exactly where in the stitch I want the Pfaff to stop. I can stop the needle at its highest point to remove the fabric, or have it all the way down to hold the fabric in place. Of course I could always turn the wheel the reposition the needle, but who would want to do that?

I have never been able to use an automatic threader on any machine I’ve ever used. I simply can’t understand them, and I have no problem threading a needle the old-fashioned way. Vintage all the way baby!

One neat little feature is this lever that can hook onto the presser foot. This takes the pressure off the foot, allowing you to match stripes and plaids easier. The Pfaff has a built-in walking foot! It’s called the Matchmaker foot. Occasionally fabric gets caught on the plastic piece, but it’s not really an issue. My biggest caution about the lever is to not leave it engaged all the time: because it reduces the pressure from the foot, the feed dogs don’t get a proper grip on the fabric, so stitches might come out wonky.

Which brings me to my biggest breakthrough: the Pfaff 1222E can use standard high-shank industrial feet. I absolutely hated the right-hole zipper foot that came with machine, and Pfaff-specific feet can get pretty pricey even without the widest selection. Meanwhile industrial feet are all over the place, and cost about $5-10 each. And they’re made for industrial use, so no worries about quality. The shape of the shank is a little different between the Pfaff and industrial feet, but the industrial shank fit on my machine perfectly (the third photo has a Pfaff foot on top and an industrial foot below; the important thing is that the knob fits into the same place). No other Pfaff site I saw had this insight, but I think the machine’s compatibility with less-expensive industrial feet is a huge bonus!

There is an adapter that lets you use snap-on feet on the Pfaff, but $70 for a foot?! That’s just nuts.

The slightly rounded plate under the free arm collects stray pins and loose threads from rolling around on my desk. I love this little tray!

If any of y’all have any questions about my Pfaff, let me know and I’ll try to answer.

For more information about the Pfaff 1222E, check out my initial review as well as my tips on threading with industrial cones. You can download the stitch pattern chart PDF here.

Hi Julianne

Loved reading about this vintage sewing machine. Guess I’m vintage too, since I purchased my Pfaff 1222E new in 1980 while in HS. Still use my baby almost everyday- runs like a dream and has had minimal repairs over the years.

That’s great to hear! I hope to be saying that myself in another 30 years.

My Pfaff 1222e is running slow. What can it be? the cord?

Sadly I have almost no knowledge on repairing this machine. I have replaced the cord on other machines (made in the last 10 years) which corrected the machine running slowly. If you can easily get your hands on a new cord for the Pfaff, that would be a great fix. Unfortunately they seem a little pricey on ebay (http://www.ebay.com/sch/i.html?_trksid=m570.l1313&_nkw=pfaff+1222+cord&_sacat=0&_from=R40) but maybe you can find a better source.

However, maybe it could also need a cleaning or tune-up. It’s so great to have a mechanic you can trust, so now might be a good opportunity to find someone. I have a guy in Beverly Hills who works super fast and is somewhat reasonable (all trips cost $90-130, which I don’t mind paying once a year to keep everything in working order).

Most mechanics I know learned their trade through trial and error, while working at a shop with an older repairman. I would love to attend sewing machine repair classes, but if I can’t find any in LA there probably aren’t many around.

When my 1222 slows down it basically needs a cleaning/oiling. Any lint/strings around the bobbin holder needs to be cleaned out… then a drop of machine oil. Open the top lid and place a drop of oil (or two) wherever you see a steel shaft going through another part/piece (needle shaft up/down, and the horizontal gear train). Then turn the hand wheel a few revolutions to distribute the oil. Turn the machine on and run at a slow speed for a few seconds to further distribute the oil. Then run it full speed. It should run/sound much smoother and faster. [good luck]

Great tip about oiling, and so true! I try to oil mine once a month, and if I forget it becomes very obvious. I never really need to oil my 2007 Singer, but it’s so easy to do this little maintenance on such wonderful vintage machines (and rather a pleasure that feels much more technical than it is).

You seem encyclopedic about the machine, do you do your own repairs as well?

https://www.youtube.com/watch?v=FjbtRB0bJvc

This guy goes through the entire machine and explains about the maintenance (where to oil, where NOT to oil) and the pros and cons. His take on a slow running machine is oil in the motor.

Also , and this is so obvious that it’s not obvious – be sure the slowness isn’t actually your pedal slowing moving away from your foot while sewing. Sure , laugh but I had this exact problem recently …

Bit of rug gripper now keeps that pedal in place for happy pfaff sewing

Thank you for the oiling tip too!

Be very cautious when bringing the 1222 E in for cleaning and oiling. They don’t require a great deal of oil. Mine was nearly ruined a few years ago because someone who didn’t know what he was doing oiled everything.

I need a repair manual. My stitch selector is malfunctioning. The A (normal position has somehow moved about 1/4 ” to the right of where it should be and I need to know if I can repair it myself. My reputable person closed shop due to personal illness and I can’t reach him .

Most likely the bushing of your front dial is loose due to the old glue failing. You can fix it yourself if you are mechanically inclined. Join the Yahoo Group, oldpfaffpforum, post your question, and if I see it I will get you going in the right direction.

You mentioned wanting a repair manual. One can be found at

http://www.quiltingboard.com/links-resources-f4/pfaff-how-repair-manual-instruction-manual-t153618.html

I got a manual on line for free. But did not have a page for parts. I did find the part online but it was 79.99 then to pay someone to put it in!

I have several Pfaff 1222E machines. My husband gave me my first one in 1982 for our ten year anniversary. I love it so much I have purchased several others – one for our second home and 7 others one for each of our children. They are an outstanding machine! I have a fabulous Pfaff repair guy that changed the settings in my pedal to make it run faster. It works great!

My machine was running slow but it turned out to be the foot pedal falling apart. Somehow the hinge came loose and it wasn’t lining up properly. When I put it back together the speed picked right up.

I enjoyed your sharing of your 1222E’s information, but I must add that the IDT (Matchmaker Foot as Pfaff first called it) is the lever you speak of that you can attach to the Pfaff ZZ presser foot as well as most of the other Pfaff feet that came with this machine. It actually does not relieve presser on the fabric, it increases it by putting a small set of feed dogs on the top of the fabric and feeding that fabric through your machine much better – thus the use for matching plaids and so on as they do not slip out of place. The whole idea with this is to get a BETTER grip on that fabric with the IDT and there is no wonky stitching that can happen if the machine is working properly! I used the IDT engaged almost all the time on my 1222E, and still do – if I am straight stitching or zigzagging or whatever – the machine holds that fabric and there is no loosening at all! When you have the IDT engaged and let down that presser foot – it has the fabric – no matter if that fabric is a thin cotton or a denim or anything else you would sew on that machine. I have had this machine since 1977 and not a day goes by that I don’t thank my lucky stars that we bought it! 🙂 Enjoy.

Wow, you are encyclopedic! Thank you for sharing all that information. I love hearing from ladies who have had their 1222s for decades. It makes me even happier with my machine, and I look forward to spending 30 years with it myself!

My sister-in-law gifted me with mine several, several years after she’d bought it in Germany and used it. I’ve used it since 1993 but have had some difficulty with it lately, hence looking for a repair manual.

hi I have just bought a 1222e which came with nothing and no book either (it has one foot and the power cord) I need to know about the feet and where to get them, which industrial feet I can buy I want to do everything ruffles bidding cording buttonholes etc and I am a basic sewer so a big adventure in front of me as I want to sew vintage clothing that fits me(any advice about adjusting patterns)you are welcome to email me thanks

I buy non-Pfaff feet on ebay. Any high-shank foot should fit your machine. I haven’t had any trouble with the invisible zipper foot, center and side zipper feet, or ruffle foot that I got from ebay. Before you go spend $200 on all sorts of accessories for your machine, I would start small and add the pieces as you need them, because maybe you never actually do want to make ruffles (I’ve been sewing for 20 years and just bought my first ruffle foot in August).

As far as tutorials on vintage sewing, there are tons of blogs and websites dedicated to sharing techniques. http://www.blogforbettersewing.com/ http://www.burdastyle.com/ http://www.craftsy.com/ http://www.coletterie.com/ http://sewaholic.net/

You can buy new feet that will fit and updated ones that the shank stays on and the foot part pops off. About $32.00 That includes all the basic feet. You can download the book of the internet for free. I was able to buy Pfaff 1222e at a garage sale for $30. It had the sales tag with it. It cost over $900 new. This is a great machine.

Yes “Michele 10 June 2013 at 6:57 PM” exactly correct

Only thing on these machines is do not over oil and get yearly clean and service to keep oil build up down. Second, they were built at a time when engineers were involved in designed and hence are actually over designed i.e. very solid and long lasting. Most of my mother’s industrial singer sewer only recently got rid of it over 70 years old, lot of feet and yes they fit.

Great comments and thanks for sharing

Good explanation, Michele. To add a bit more, the IDT foot moves in an “elliptical” pattern. At the end of the feed dog stroke, the feed dogs drop and then move toward the operator. The feed dogs then rise to grab the fabric and move the fabric away from the operator. The IDT foot mirrors this action. That is, at the end of the stroke, the IDT foot rises away from the fabric before moving toward the operator. Then the IDT foot drops as the feed dog rises and the fabric is trapped between the two. The IDT foot remains at its lowest position while the feed dogs are at their highest position, and both pull the fabric away from the operator.

Of course, this assumes that the machine is properly adjusted.

Not sure if you are still following. But I need to disengage matchmaker foot to allow other feet to be used. But do not know how to disengage. Inherited machine from Aunt. Love it but sadly she is gone and I cannot ask her. TIA

I have two Pfaff 1222’s and you mentioned the needle position at the end of stroke when letting off the gas, but you never mentioned the needle positioning from the presser foot lever. When the presser foot lever is pushed down below the free setting, it leaves the presser foot down, but moves the needle automatically to the highest position. Alternatively, you can put the lever up to its resting position and then push up beyond that to get the needle to its highest position and to lock the machine from turning. This also disengages the motor for bobbin winding. Great features – and I know not quite what you meant, but automated top positioning is handy once you get used to it. Too bad there’s not a bottom position though…

Thanks for your blog – I’ve learned a few things from it re. the walking foot – had no idea it could be disengaged. Now I know!

AF

Hi Andrew!

Maybe it’s just my machine, but when my foot is down and I lower the release lever, my needle does nada. But yes, I love pushing the lever up and the needle goes up. Unfortunately, since getting my Pfaff back from a re-timing a few weeks ago, the needle pickup movement is so slow. It’s annoying, and I need to drag myself back to Beverly Hills (and spend those 2 days revitalizing my Singer 401).

Did you read Michele’s comment about the walking foot? I LOVE getting these great tidbits from people who have had their 1222s for decades. I’m working on a post about little threading cheats I’ve figured out, so keep an eye out for that in the next week or so.

If your Pfaff moves the needle up when you push up to the highest position on the presser bar lever, but the needle doesn’t go up when you push the presser bar lever down to the lowest position, then your Stopmatic needs adjustment.

Also, the speed of the needle pickup movement is adjustable with potentiometers in the electronic speed control box. See the service manual.

Finally, you mention stopping the machine in a good position to remove the fabric. If you take your foot off the foot control, then move the presser bar lever up to the highest position to free the fabric and activate the Stopmatic (needle up function), the needle will be out of the fabric and the top tension discs will be relaxed resulting in the minimal tension on the thread to easily remove the fabric. This is a little easier than finding the optimal position with the hand wheel.

In addition, using the Stopmatic to raise the needle puts the needle in the optimal position to use the automatic threader. Of course the threader has to be properly adjusted to work correctly.

Love these machines I have 8 all together- 1st one I got was in 1990 traded a brandnew Whites that I could not get to sew thick fabrics for it. And used the heck out of it from then on but now the shuttle cock is out of time with the needle. So been bidding and buying them off ebay-I sew a lot of wedding dresses for deisgner heidielnora.com – 75 to a 100 a year. out of the 7 others only two have acctually worked. but none correctly most have problems with the stopmatic where the foot raised up completely when the foot lever is lifted as high as it will go. This is so you can pull the thread out from the foot to cut it without turning the sheel to let thread out. Love that part. Also the circuit boards are usually the problem with most of the machines as they cannot take power serges like the ones today can. and the majority of machine repair people do not actually know how to fix the machines. I mean more than oiling and aligning it,as I have tried several. But I have found a guy in PA that can actually refurbish these machines.Hhe builds new circuit boards and replaces parts plus he can fix the motor if needed He actually takes the entire machine apoart and fixes and repaires it. Check out his web site Kennsplace, he has repaired 3 of mine and I get the new circuit board all of them. I just sent him another one and have two more for him to refurbish. I love love love these machines. I hate sewing on anything else…Anyway if these machine sit for a long time they will have problems ususally with the circuit board. Rarely with the motor. To be so old these things werehigh teck back then. All of them are 40 years or older he can tell you when it was made also. He does work on later models too.

I had my machine refurbished by Kenn in 2012. He did a super job delaquering of hardened oil and repairing the slo-mo foot pedal that never worked right for me. She’ll never be fastest machine in the house by design, but is the best for durability, heavy duty sewing and stopping in a dime. It was 11 1/2 months before I got her back though, due to Kenn’s backlog of repairs. Make sure you have a spare machine before sending her away! I bought a Janome 3000 for the interim once I realized I may never see her again.i got her back the week after Christmas, 11 months after I sent her in. I was very satisfied with his workmanship. Just don’t nag him like I did and you may get it sooner. If you know up front how long it might take and multiply by 3, you won’t panic.

That’s quite a wait, but I’m glad to hear that it was worth it. Hopefully you weren’t charged an arm and a leg as well!

Well, it must be the same for answering emails because I still have not heard from him. I guess i will keep trying

How frustrating! As if a broken sewing machine weren’t bad enough.

I believe this service man died in 2016 or 2017. so I think ill health was the problem.

I am a Pfaff 1222/1222e devotee having bought my first 1222 in 1971. I don’t believe that there is a better machine – I have since purchased a second 1222e and also a 1221, so I always have a backup machine. The fact that these machineus are so hard to find second hand is testimony to their worth. So many features and easy to use I would recommend them to anyone.

I got my Pfaff 1222E for college graduation in 1980. I have made maternity clothes, baby clothes, home decorating items and now am quilting on it. It has been a tank in a world of cheap machines. There is really nothing made now that compares to it. I think it will go another 33 years!

Thanks for your comment. Pfaff was my dream machine, and I feel like I really lucked out with this baby.

love my 1222e, I am a 1222e devote too, got mine in 1979 and learnt then that it came out in 1970. What a waste of time i had not known it for 10 years. 😉

Mine is having problems with the outer setting dial for the stitches.

How do you think I feel? I only got mine in 2011!

is there a difference between 1222 vs 1222e ? They both have electronic I think

I found this little list: http://www.kennsplace.com/1222differences.htm

But I think generally, they are the same.

thank you very much for the link and the fast reply

“The 1222E has a thread cutter on the back of the IDT (Walking Foot); the 1222 doesn’t have a cutter.”

FYI

My 1222 does indeed have a thread cutter on the back of the (Walking Foot).

Mine has a tiny little thread cutter on the back of the walking foot as well, which I never use. I prefer my sharp Gingher snips! Do you ever use your cutter?

That little notch isn’t a thread cutter but it does work as one. It just happens to be there. I use it occasionally but I’m in the habit of using small scissors anyway. An it is the only difference I’ve found between the 1222 and the 1222E. My machine lady told me they are the same – ie both electronic – the “E” is a model year newer. I bought my 1222 in 1975 just before the 1222E came out. Still sewing on it but in constant use (like machine quilting or sewing for 4 hours at a stretch) it “runs on” – just keeps going with out using the foot pedal. But I give it a rest and when I come back it works just fine! Guess it’s feeling it’s age just like me.

Hello-

I bought my beloved 1222 in 1973. Alas, although I cannot bear to part with her- we’ve been through so much together- she no longer runs and cannot (so I’m told) be repaired.

I’ve tried to replace her but cannot find another machine worthy of kissing the hem of her skirt! My wish is for Pfaff to do a special, ‘vintage’ re-issue of the 1222 or 1222E as many of the car manufacturers have done in past years. Bet they’d have a waiting list!

When I bought my old girl waaaaaay back in the distant past of the 70’s (my god! We didn’t even have PCs in those days, let alone cell phones!) she was just a 1222. However, Pfaff had come out with the 1222E (‘E’ for Electronic) and offered to upgrade the 1222s to the ‘E’ for a nominal fee so I had her ‘E’ installed. As I remember it, all that actually did was to add stretch stitches which the 1222 hadn’t come with.

I loved that trusty old machine like a pet and she flew with me to many on-location film sets- I worked her hard all her life and she always came through like a trooper. I no longer sew professionally but I’d buy another 1222 in a shot if they were to re-issue that machine. Sniff.

Me too! I also own a 1222E and a 1222SE. They just seem to have more stitches with the buttons on top. The 1222E needs a new camshaft but it sews just fine on the straight and zigzag stitches. So I’ve taped the button compartment shut till I can find someone who is competent to install a new camshaft.

I have a 1222E. The dog chewed through both cords from machine to foot pedal and to electrical outlet. I’m trying to repair it and need to know if cord to outlet comes out of the top or bottom of the plug that attaches to the machine. Your help would be much appreciated. I haven’t been able to get a picture to show me.

Hi Eileen, If you hold your plug machine end facing you the left wire goes to the foot pedal and the right to the wall socket. (If it is plugged into the machine it would be the bottom wire to the foot pedal. That’s how mine is set up but it must not make a difference because the picture in the manual shows it opposite.

The label on the bottom of the pedal says PFAFF Typ AT 0023 110 – 240 V ~ 50 – 60 HZ

For use with Pfaff sewing machines only types 1221 and 1222 Listed 351 C LR 13364

Made in West Germany It has the CSA stamp and the UL stamp also.

Hope this helps. Bonnie

I found this

http://www.allbrands.com/products/26090-foot-control-and-cord-90-222040-08-for-pfaff-1100

I have a 1222E that I bought in 1979. New it was $1200. Cdn. I’ve been offered $500. for it but am not ready to let it go. A friend of my mom’s had a 1222 and I was really impressed with it. At that time Pfaff used to advertise that it was so powerful it would sew lengthwise down a wooden ruler. I had it demonstrated for me and couldn’t believe it, never did it myself though for fear that I would damage my own machine. I’ve sewn through 5 layers of denim and also 6 layers of wool with no strain at all on the machine. I call it my work horse. I understand that the main difference between the 1222 and the 1222E is the Electronic foot pedal. It seems to give it more adjustable power even at slow speeds. One other thing that is a good thing to note is that if you can buy a long shank adapter you can then use any of the clip on feet that Pfaff sells on this machine. I’ll take a photo of it and post on this site. For Eileen, I will take a photo of my plug for you so you can see what goes where.

I understand that parts are hard to come by but if you ever find an electronic foot pedal for sale buy it as a backup. You won’t be sorry. I now have a newer Pfaff Quilt Expression 4.0 Made in Sweden. It is great for piece work and has a few neat functions but not the power and weight of my 1222E. I have the original instruction book and another called “Ideas and tips for your sewing ease” that both came with my 1222E machine. I also have the original chart that shows what the stitches look like in colour. I’m willing to share if anyone is interested.

I am giving my 11 yr old grand daughter a 1222e that I found on sale used. It has no book and I would love copies of the 2 books you mentioned. Let me know how much. Hilgy

I bought my 1222e in 1976 while in Germany. I have the original parts and book. I do not remember “Ideas and tips for your sewing ease.”

I made most of our clothes while in Germany as well as stitched on patches for my husband and most of the men in his section. I can attest to the ability of this machine to plow through many layers of denim. Mine had a long vacation while I attained my masters but came out of storage to make a denim quilt with no problem.

I love my machine. I expect to make many cute dresses and quilts for my great granddaughter.

I would like to find someone who has the parts book for the 1222 and would be willing to copy it. Also if anyone has the Original color digital owners manual that would be greatly appreciated as well. Thank You

Steven Smith

Hi, I do have Pfaff 1222 need Instruction book, Ideas and Tips also stitches chart so I can start sewing.

Best Regards

DP.

You mentioned that spares may be hard to come by. I found this site

http://www.sewingpartsonline.com/pfaff-1222-sewing-machine-parts.aspx

I do not have my Pfaff manual, I am having problems with getting the stitches adjusted. The metal ring around where you change the stitch length fell off and I have had the machine repaired and he said it was worki8ng fine, but it doesn’t. Does anyone know if you are suppose to adjust the bobbin tension or what could be wrong. I played with that ring and repositioned it until I can get the top of the fabric stitches fairly good, but the bottom is so tiny until you cannot get them out.

Sandra (http://brownpaperpattern.blogspot.com/) adjusted my bobbin tension a few months ago. Previous to that, I always had to loop my top thread around the bobbin winding tension disk on top. However, I’m not sure how related tension will be to your stitch length (they definitely effect each other). Are your feed dogs working properly?

I’ve had some issue like this with stitch length, etc. Someone suggested I was using the wrong size needle. Not sure that was correct.

My wife Pat purchased her 1222E new in the early 80’s. We pickup up a second one last year. Both are in great shape. I came across this Youtube video you should watch if you have one. It last’s over 30 minutes and covers just about everything about your Pfaff.

My 1222 machine purchased with cabinet at the then outrageous cost of ~$900 in 1971 has made curtains, bedspreads, men’s blazers, little boys clothes, pillows, my entire wardrobe for decades, quilts and yards of old jeans denim “things”. The last decade saw less use, so I took it in for a tune-up, cleaning and any repair needed a year ago. That seemed to work fine until I was sewing the other day and changed the empty bobbin then found that it would sew a few stitches, lock up in a tangle of thread around the bobbin case and grind to a halt. Is this a tension problem? I’ve never had to deal with tension adjustments in the past, so don’t know how to approach it. This machine has been a workhorse of the highest order and it was worth double the price back then. Hooray for German quality manufacturing. I’ve been able to resist the fancy digital temptations based on my long-term relationship with my 1222, but I do need help now.

Hi Carolina,

It sounds like a tension adjustment might help out. There is a dial on the left of the machine with which to adjust. I find that different types of thread, and whether they are on a spool or cone, can require vastly different tensions. Thread type on the bobbin can also throw everything out of whack. It can be mysterious sometimes. I’ve also experienced terrible stitching that’s remedied by a new needle. Try these approaches on scrap fabric, and I hope you’ll be successful.

Otherwise it’s great to hear about the longevity of your machine! I certainly love mine.

If you have an Operators Manual, it has a decent section on adjusting both tension controls.

It must be the tension then as I continued to use the same kind of thread both top and bottom so I’ll pursue that. Thanks for your recommendations. This machine has many miles to go.

Thank you for posting this blog. I have had my 1222E for years now and truly love it! I also got the machine 2nd hand and bring in for a tune up every year. It needed some new parts years ago but since then I have had no problems. The machine does not need oiling except for the bobbin race wheel and I have been using a regular 3 in 1 sewing machine oil for that but the I was told by my technician just recently that I should really be using automatic tranny fluid (yup, for your car) for that instead because the 3in 1 oil gums up or better said it attracts lint and dirt to itself. Using top quality thread and Organ needles have really made a difference as well.

I do have the shank where the feet can pop off and it does make things easier. I just need a straight foot now, thought I had it but, it may have walked off.

Great to part of a wonderful community!

In 1973, bought my Pfaff 1222 new while living in Germany. They called it a Pfaff 1222E but the “E” is not on it. I cannot find the chart for making combination decorative stitches. Can anyone help?

I have 2 stitch pattern charts! One has 42 designs, and can be seen here: http://www.siadek.org/madebyjulianne.com2/wp-content/uploads/2013/10/stitch-pattern-chart-42.pdf

The other has 60 designs, and is too big for me to upload to the site. I’ll work on resizing it if anyone wants to see. In the meantime, try Google Docs: https://docs.google.com/file/d/0B5KrQv522fGoS2FoWUd4RllkX2M/edit?usp=drive_web

I also have the PDF manual; happy to share that as well!

Hi. I recently received my Pfaff 1222 as a gift from a friend and, like the rest of the folk here, I LOVE it. It is a dream come true. It didn’t have the extension arm and I would like one. Do any of you know where I could find one? There is one on Ebay right now, priced a little higher than I can afford. Thank you for any help you can give me.

I have three 1222’s – well a 1222, a 1222E and a 1222SE. I have to day the 1222Se is not quite the machine the other two are. Just a bit “looser” or maybe fmore finicky. But I love ’em Bought my first one just after I got engaged in 1975. All my girls learned to sew on it.

Problem with the oldest one – with a lot of use it starts to “run-on” without me touching the foot pedal. Need to turn it off to stop it. Stitches are still good but makes scary noises. Of couse it won’t do it for the one repairman who knows Pfaffs. He cleans it a pronounces it good. I use it for a while and it starts up again.

Maybe it shouldn’t be used 8 hours a day?

On occasion I’ve had the same problem with “runaway stitching.” It seems to happen when I’ve been pushing on the foot pedal for a while, going through heavier fabric: hemming drapery mostly. I have to turn the machine off to stop it from racing away.

This hasn’t happened in months, and the machine always seems to work fine otherwise. If your mechanic comes up with any insight, please share it with us here!

Here’s the link for replacing the pedal: http://www.siadek.org/madebyjulianne.com2/replace-pfaff-pedal/

Hello Julianne

I just bought a Pfaff 1222 electronic and it is permanently on?

I took the pedal apart and cleaned it, no change.

I looked the electronic board over and it looked fine to me no burnt marks or disconnects.

I even connected an old pedal and no change.

Apparently it is running permanently all on its own even with the pedal disconnected?

So I was wondering if someone had changed the way the power was connected to the machine? Mine seems to have the 120 hooked to the top two pin ins?

Any help would be appreciated, even a picture of how the pedal and power are connected to the 4 plug pin.

Sincerely

Greg Byrne

I just got my Pfaff 1222 yesterday. I can’t seem to get the presser foot to go all the way down against the bottom plate.

Please excuse me if I’m not calling the party’s by there proper names. I’m a total noob.

My initial thought is that you have a low-shank foot on the machine. It’s about 2-3 mm shorter than a high-shank industrial style foot that the Pfaff uses. The high-shank foot is 1.25″ tall, from top to bottom. In case you’re not familiar with this part or where to buy it, it’s at the end of this post.

Please comment again if that still doesn’t work; I’m so impressed and amazed by the helpful replies from other commenters!

Thanks for helping. This post is one of the reasons that I bought the 1222.

When I get off work in going to check that.

One more thing I noticed was it looked as if the foot was moving slightly up & down. Similar to a walking foot. Not just the IDT but the foot itself.

When I take the high-shank off my machine (so that there is no foot on at all, and no pressure) the shaft moves up and down with the needle. So we might be on to something with this low-shank theory!

I love that this has become a forum to discuss the 1222. I would love to learn to do a full service on the machine, and then post pictures and advice. I was very lucky to stumble across the machine, and my husband had it mailed from an island in Washington as a gift. It’s such an essential tool to my work and life!

It looks like a high shank. The IDT foot is even with the bottom of the presser foot.

Can I post pictures?

I can email them to you or anyone if you send me an email with pfaff in the subject line.

rsdonovan1@gmail.com

I fixed it!!

Like I said I just bought it, and it had been serviced and a new cam stack put in.

I took the cover off that hides the light and apparently who ever did the servicing dropped a screw inside the machine. It had worked its way down between the IDT arm and the machine casting where the IDT/presser foot arm comes out which would not allow the arm to come all the way down.

PHEW!! Now back to learning how to sew.

Thanks for your help.

Spanner in the works, classic. I’m glad that you solved it, and if you need any help with sewing feel free to ask/email!

Good detective work! Glad for you nothing got damaged either.

I also love my 1222, the walking foot is great for sewing in general and perfect (required?) for sewing kites. Yep, I said kites, I have about 40 and have made 4.

I have just received a CD with two excellent service manuals (written by Pfaff!) and an exploded parts list as PDF files. Do a search for ‘pfaff 1222 service’. Other manuals can be found there, too, so if you need a user manual, try ebay.

I had the dread cam split problem a few years ago and found, also on ebay, a replacement cam that had more stitches – stitches that I don’t use much – I believe it’s the same one that gets 60 stitches.

Thanks for the tranny fluid tip.

Hi Brian,

I have a Pfaff 1222e, but the master on-off switch popped. This crucial part was spring-loaded with a flimsy spring and a plastic part. After accesing it, I realised that this plastic part broke and I wanted to ask you if you could lend me your exploded parts list as PDF file (I have the service manual but it doesn’t say a thing about the switch). Hopefully you can help me, thank you very much in advance.

Hi Paula, I’m going to email you directly. Good luck!

I have a Pfaff 1221, (same machine as 1222 except it doesn’t have the free-arm), which I bought from an ad in the PennySaver in 1996, and I’ve been sewing with it and loving it ever since!. My machine came with the 1221/1222 Book and the four-color chart of 60 stitch examples. I’ve sewn everything from apparel to drapes and sheers on it. Only issue was not long after I got it, the belt went out and I had that replaced at a repair shop. The repair shop tried to buy it from me, by offering an incredible deal on a new machine. And I mean he really tried to buy it by talking me out of this machine and expounding on the benefits of the new machine. (He really wanted this one!) I said no and I’ve been very glad I still have this machine. They are in demand and accessories and feet are rather hard to find.

Prior to my Pfaff, I had purchased new, computerized, Singer and Brother machines which I quickly sold because they didn’t have enough power, were generally cheaply made, and couldn’t sew a beautiful straight stitch. I have to say though, I just bought a Brother Project Runway XR9500PRW for my daughter, which has been pretty impressive so far. Doesn’t seem to have quite as much sewing power as my 1221, but very easy to use and a ton of stitches. They have worked out a lot of kinks on the computerized machines, and my daughter should have an easy time learning to sew on this machine. We’ll see how it performs on various projects.

The Pfaff 1221 has been fantastic and I would recommend it to anyone.

Good to know that the high shank industrial feet work on this machine, I’ve been eyeing them on Ebay. So far I have always used the Matchmaker foot because it feeds the fabric through evenly, but would love to try the heavier industrial feet for straight stitching, especially on sheer or lightweight fabrics, because sometimes they can get pulled down into the feed dog, unless you use a piece of tissue paper underneath. A specialty straight stitch foot with a single hole for the needle may also do the trick–I’ve been looking for one of those, as well. Also considering buying the shank extender so I can use the newer Pfaff snap-on feet, but they charge $60-$70 for that shank, while the Pfaff low shank extender is only around $12–why is that?

For those wondering about the jamming issues–always check the upper threading and the bobbin, because sometimes these can become unthreaded in certain spots without you realizing it, and for the most part, issues have been solved by ensuring proper threading. Also, after using the functional or decorative stitches (by pushing any of the ten black buttons under the cover on the top), make sure these are disengaged afterward by pushing on the little black button on top of the machine, and making sure all of the ten buttons are in the “up” position, otherwise the machine may not sew correctly, and stitches may be a little “confused.” Also make sure the bobbin thread is going in a clock-wise direction and coming up from the bottom when held in your right hand. Insert into the bobbin case exactly this way, then pull the thread up around and down into the bobbin slit.

Also, I would agree with others who recommend oiling about once a month, otherwise the machine can become a little slow and mechanical sounding, as it’s working harder than it needs to. The tranny fluid was a great tip–thank you. Finding the service manuals is a great suggestion also–thanks, I’m going to look for those.

I’ve also had the “motor runaway racing” issue, but very infrequently. Not sure what causes it or how to avoid. If anyone has any insight, it would be greatly appreciated.

Thinking of buying a cover stitch machine. Has anyone used one they would recommend?

I recently bought a Singer from the 70s or 80s for $15, cut off the foot pedal, and spliced it onto the wires for my Pfaff pedal. So far, no runaway stitching!

The issue seems to be a tiny lead knob in the foot pedal that acts as a resistor. When I opened my pedal up, this little bump just fell right off! I consulted with my favorite electrical genius and the guy who originally sold me the Pfaff, and it seemed like it was going to be a pain in the ass to repair. Replacement pedals with the electric plug are about $80! I’m planning on posting about this next week.

As for the snap-on foot adapter, I actually found one for about $20 (but now I can’t find the link)… and never use it. I don’t really have that many snap-on feet, and I’m happier with the high-shank industrials (which cannot be used with the matchmaker).

Thanks for sharing your experience!

If I ever find an electronic foot pedal, I’d like to splice it onto the wires for my Pfaff. However I’ve had the foot pedal changed by a sewing tech and I’ve switched foot pedals between my Pfaffs and my 1222 still likes to “run on”. So I’ll just keep giving it a rest until I have the $$$ to get an original foot pedal.

Hi Julianne and all,

Glad I found this “Pfaff update” site. I bought my 1222e in mid seventies and do not think I need a new sewingmachine with the first- it works.

However I have read about “overedge feet” on the nett and wonder if you know of one that will fit 1222e?

I have always thought it was difficult to get the “castover” seams good on fine fabics and may be such a foot could help.

Howdy,

I’ve played with a rolled hem foot on a low-shank machine, but never took the time to master this technique or tool. You can find some high-shank feet on Ebay.

You can also make gorgeous tiny hems without a special foot: http://grainlinestudio.com/2011/08/17/tips-tricks-easy-roll-hem/

It was a nice rolled hem which I will try to remember how to make. But I just looked for a foot that would make the seam allowance lie flat when I finish it – not be ruffled..

(I am not so good in english sewing terms)

After searching for “overedge high shank” for a while I changed to “overcast” and found this:

http://www.sewingpartsonline.com/overcast-foot-high-255h.aspx

which I ordered and hope will fit and do what I want.

I have a Pfaff 1222, vintage 1973. I purchased it in Germany at the US Army PX. It is a 220 machine and converted to 110 when we returned to the States. I have had minor things go wrong and repaired no problem. I had it overhauled 6 years ago,the motor was cleaned. How is this machine different from the 1222E? I even have the Pfaff cabinet for it that allows for the free arm or flat table sewing.

Hi I have had my 1222E machine for about 35 years and I cannot remember how I used to sew on very stretchy fabrics..I forget the stitch that goes 2 fwd and one back…How do I get it to do that? Thank you

Here’s a link to the stitch pattern chart. I hope it helps! http://wp.me/aWv22-1u5

Hi Susan,

You’ll find lenghthier explanations in the other comments on this page, but the E has an electronic foot pedal. However, some of us have had problems with the foot pedal getting stuck, which results in “runaway stitching”. I’ve since spliced on a different control pedal, so I’m not sure if my machine still qualifies as an E!

Hi Susan,

I was just given a 1222SE, with the 220 power cord. How did you convert yours to US current? is there a European to US converter available? I’ve never looked for one, so don’t know if one is available.

Thank you.

For stetch fabrics, is there any stitch that would be the best to use and which of the buttons do you have to push or set to on the Phaff 1222E machine? I don’t think it says in my manual..Can’t seem to find it anywhere in the book. Thank you

Linda, I’ve had best results using the plain old zigzag stitch. I like the wider stitch (about 8.2) for most fabrics. This is what I use for most of my stretch hemming; I have a serger that I use for seams so another sewer might have better/different advice. Happy sewing!

Just a comment … for stretch sewing – generally I use the longest narrowest zigzag. Set the dial to the farthest point of the 5. Sewed hundreds of tshirts and stretch fabrics using just that stitch. There is also a triple straight stitch (two steps forward and one step back) on the buttons that can be used for a very curved seam or for stretch fabrics. The narrow zigzag is faster thought.

I’ve had my pfaff 1222e since 1982 and it’s reliable and efficient. I love it. My latest project was hemming some sweatpants. I had forgotten how to sew with jersey knits, it’s been a while. I ended up using the overlock stitch and that worked very well.

I’m having a problem with the stitch length though and even the number 4 stitch seems to be short. I think the dog teeth may not be pushing the fabric through enough. Any hints?

Someone is selling a Pfaff 1222E in my neighborhood and I was wondering what I should pay for a secondhand one. I currently have a White and a Singer but am looking for something a bit tougher. I have gone through 2 clutches on the White (my techie cannot understand why) because I sew 100mph all the time! Is the Pfaff 1222E for me? I have a ton of leather, denim, fabric that I want to do projects with and I fear it will kill the other two.

Hi Suzanne,

I paid $300-$350 for mine in 2011. It had been fully refurbished by an independent mechanic, and came with a few random feet, as well as the original extension bed and case. This seems like a pretty common price. How much is your neighbor asking?

I’ve sewn leather, vinyl, upholstery, all without any problems. The only thing that consistently throws my Pfaff off is sequins, and sometimes lamé! And so I had to teach myself to adjust the timing. I always do it when I’m a little tipsy, because it’s too scary to do sober (and not too difficult that it can’t be done drunk). Though this technique has totally worked, I can’t create a tutorial because I don’t remember the process once I’ve dried out.

I’ll have to check if my sewing guy likes to work on the machines when a little tipsy!

Love this site so many helpful hints and links.I’m from Ireland and it is difficult to get parts,thank goodness for eBay !!!

And how! I feel fortunate to have lived my entire adult life with eBay as a resource.

Just found your blog. Great comments. But I just had to add one or two myself.

I laughed at the needle threader when I bought my 1222 in 1980, at age 25. The shop owner smiled and said I’d think differently when I got older – and I do!

Also, having used industrial Pfaffs (and Berninas), I did know that you can use those feet on your 1222.

What I really love is that, like my pro machines, is that you can tweak the top & bobbin tension to go from chiffon/silk to leather patches on backpacks – handwalking the needle through, of course. But with no stitch skipping or other acting up.

My sister swears by her 1956 Singer, like my mom has, but I love that Pfaff!

I’ve had my Pfaff 1222 since 1974, and it’s been great. For a few months now, it has occasionally refused to quit sewing a zigzag even though I have reset it to a straight seam. Until now, I have been able to solve that by rotating the needle position dial several times, but today, that does not work.

Now, it only sews a straight seam when the needle position selector is set to the right hand position. Of course that means I can’t sew down the line I used to sew, because the seam is in the wrong place; I have to sew on an edge, to get a seam in the center.

Does anyone know what part I need to replace, and better yet, where I might get it. I am in the Caribbean, so sewing machine repair is problematic.

Hi Julianne, I have had a Pfaff 1221 since sometime in the ’60’s and I bought “USED”. It has been great and lots of use. Due to illness it has not been used for about a year. t has been cleaned and oiled and suddenly will only sew backwards. Any suggestions? Thank you, Eleanor

Do you have the Reverse lever vertical?

Each time my designer 1 goes in for service or repair (always pricey). I pull out my Pfaff 1222E purchased in 1978,

How I love this machine, it sews so well with good straight lines, I bought it when we lived in Singapore where it happily coped with the heat. Now back in Australia with a different climate it has never yet failed. (touch wood) it has never had a service just a husband who has cleaned and oiled it. Only fault is that’s it’s heavy but perhaps that is why it has lasted so well. As the saying goes, “they don’t make them like this nowadays”

I too love my Pfaff 1222E. I live in Louisiana and had to go to Houston for service but they can’t fix it so I have emailed Kennsplace. Sure hope he can repair it because I think it has a broken feed gear. The new ones seem much too complicated for me and I want to get this one fixed if at all possible.

Hi, did you ever get your machine back from Kennsplace? I sent mine off in May 2015 and I still haven’t received it. He won’t answer my emails either. thanks, Rita

I meant May 2014.

That makes me sad for you! I’m glad to know this in case I ever need repairs.

you can’t get new spare parts anymore from the fabric, I asked !!! you can only hope to find old spare parts somewhere.Good luck

I believe that Kenn passed away in the last year or two. He may have been in ill health before that and that’s why you never heard.

I bought the 1222E brand new, and have loved it. It is my workhorse, that has sewn many items. From repair a canvas tent, home decor projects, kids furry sleeping bag, upholstery. It sews so nicely and I could not bear to trade it in when I upgraded to a new machine. The high-low adapter is available at different source and should only be under $20.00. I have seen them on ebay for as low as $6.00. I have one and have been able to use any pfaff foot that is snap on. Also singer had some high shank feet which do work on this machine as well.This amazon High Shank Snap-on Adapter 5011-2 is only $3.52 plus shipping. It will work as this is what I have.

I loved my FIRST Pfaff 1222 so much I have since bought 4 more. My original one has a problem with “running O” or “Ghost running” but I remain hopeful it can be fixed. If not the camstack is only about 3 years (old from when I replaced it till I quit using it regularly so it can be used for spare parts. Am going to try it out with a new to it foot control to see if it just needs a new foot control to stop the ghosting.

Awesome machines!

Does anyone have the updated version of the repair manual for Pfaff 1222 or 1222E? I know there is one. I downloaded it before along with the older repair manual but I have misplaced where I stored it.

Thanks for any help.

Rita

Do anyone know about instructions of how to replace a broken gear on a 1222e?

Would greatly appreciate any help.

Gudny

hi.

I got a good laugh, I have had my 1222E since then ( 1982), it very,very worn now, have made tons of clothes, curtains and doll clothing over the years, it can no longer be repaired, so I give it a little oil and speak sweetly to it – and hope for the best, but I must soon out and look for a new one.

regards from Lisa in Denmark

am sure that your 1222e can be repaired nothing is impossible I have just bought a second hand one it has no foot pedal etc so cannot use it yet but also have found the feed dogs do not move any ideas on a possible reason why am in uk but there is nothing much on uk ebay and its not worth getting one from the states too expensive and different voltage

Since my 1971 Bernina gave up the ghost, I recently purchased a Pfaff 1222 at an antique mall. So far, I’m very happy with it but it came with only a few presser feet. I’d like to get an original roll hemmer foot. The after market one I ordered from SewingPartsonline.com fits the machine but does not have the slot in the back that allows the IDK lever to function. Since I’m trying to hem lightweight silk and chiffon, it does not pull it through evenly.

Any suggestions on where I can find original presser feet?

I have a Pfaff 1222 I bought for my wife when we were first married in Italy in about 1973. It’s been a great machine and the quality is well worth the what I thought was a really high price as a young airman. Unfortunately today the foot lift lever seemed to be stuck when the wife got the machine out to use it. Trying to free it I guess I put too much pressure on it and it broke. I have found replacement part and have it on order, but I can’t seem to find anywhere I can see how to do the replacement. I know how to get the covers off and think I know where the set screw is to get it out, but I afraid when I pull it out the pieces will go all over the place. Are they spring loaded or does the lift lever just slide out so a new one can be inserted? Thanks and great blog.

I have a 1222 that I bought in Germany in 1975. It is my only machine and has served me well. Over the years, it has been in the shop only twice. I am now starting to quilt and need a stitch in the ditch foot that can be used with the matchmaker foot. Does anyone know where I can get one?

Hi Julianne,

great website you have got here, loads of info… thanks!

I also baught a PFAFF 1222 just recently and absolutely loving it. I used to sew kites around 10 years ago with my mum’s machine(singer) and now that I have a little more time for myself I got back into sewing.

I liked your article where you explain how to use big bobins so that the thread doesn’t tangle or become loose. I had some problems with that so far, but I’m working my way around it.

Can I add a link to your website from mine?

ciao

Danny

I just got an ebay 1222 and it has many problems. I can return it for a full refund, but I still want a 1222 so I’d like to have it fixed, if not too much $$$. I have asked the seller to share in the cost….still waiting for a response.

The SS is a very narrow zz, and the stitch selection wheel sometimes changes the stitches and sometimes not. The needle position dial will not put the needle in the right position. I cannot do a satin stitch in any zz because the fabric will not move and the stitches just pile up (wrong foot??? I don’t know.) There is a “hitch” somewhere, the wheel moves smooth until a certain point, then catches. I took of the top and bottom and the gears i could see look fine. Can this be fixed??

Help! I’ve borrowed my mums Pfaff sewing machine, cannot for the life of me get it back into its case with all the parts.

I have found some websites that help with repairs for slow running 1222e’s.

I am about to try. More details later

http://www.electro-tech-online.com/threads/is-this-a-three-leg-capacitor.94810/

Some more circuits here

https://www.drachenforum.net/index.php/Thread/67641-Pfaff-1222-und-die-Elektronik/

I don’t have a repair manual for the Pfaff 1222E.How do I get one?

What a treasure trove these comments are!

My husband gave me a 1221 in a cabinet for Christmas. He bought it from a lady for 150! I’m realizing from reading the comments what a GREAT DEAL that is! I’m trying to learn to use it… The sewing machine I’ve been using is a little Kenmore that I bought at Sears. The first time I sewed a line on the Pfaff, my eyes got big. It’s sooooo smooth! Comparatively speaking, the Kenmore “gallops”! So far. My biggest challenge is getting the tension situated. The lower tension seems loose and I can’t quite figure out how to get it balance. I’ve tried adjusting the screw on the bobbin case as the manual instructs, but so far haven’t been successful.

Ideas?

Hi,

You’re so knowledgeable about sewing! I’m SO not!! My mom was a great seamstress & owned a Pfaff 1221. I’ve scoured over the internet (to no avail) in the hopes of finding how I can (IF?) acquire more stitches for my machine. This machine is from the later 70’s for crying out loud, but there’s no need for me to buy a new one w/my lack of sewing skill. I have a project at my church that I need a particular stitch that is not on my machine.

A local Pfaff dealer told me to go to Pfaff.com & that my machine was capable of 200 stitches!!! The machine only shows about 8 or so. Is he kidding?? I mean, it has no software to be downloading something. I can find no such information to that effect in regard to this machine. He also said the 1221 & 1222 were practically the same. I notice yours looks a lot like mine. HELP, advise me if you can!

Thanks,

Donna Schnaath

check out the stitch charts posted higher up

Hello, all the tie i used too check website

posts here in the early hours inn the break of day, because

i enjoiy to learn more andd more.

Hello, i see that your site loads very slow, it took around

10 seconds to load this article. Do you know

that website speed is major ranking factor for

google now? If you speed up your page loading time you can rank

higher and get more targeted traffic. There is

simple method for faster loading, search for: Masitsu’s tricks